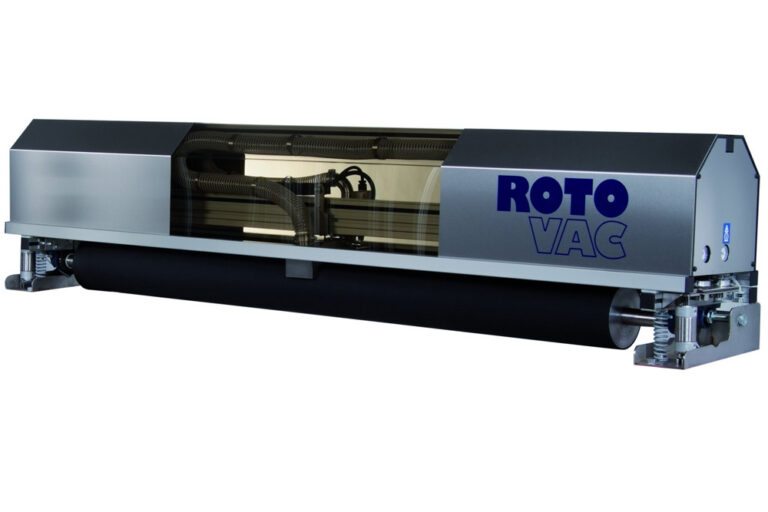

Rotovac

ROTOVAC FOR FLAT SCREEN PRINTING

FREE delivery on all orders over £75

Delivery in 2-3 working days

- Unique double roller design

- Rapid roller start and stop

- Reduces printing faults

- Automatic roller changeover

- Printing widths 1.8m – 3.2m

Features & Benefits

Patented

The utilisation of a unique patented double roller design enables continual lint and dust removal during the flat screen printing process, helping to minimise printing faults and maximise output. The ROTOVAC cleaning technology is unique and has been further developed to offer this double roller configuration. It allows for the rapid start and stop process of flat screen printing whilst maximising lint and dust removal.

Light weight

The unique and patented lightweight roller system offers versatility of operation as it enables the rapid start and stop process without any negative effect to the fabric. An advanced low weight roller design minimises roller inertia during the start and stop process, this enables successful processing and cleaning of knitted and woven fabrics so reducing printing faults, improving quality and maximising output.

Advanced electronics ensure continual cleaning and integration with any printing machine.

Rapid start & stop

ROTOVAC for flat screen printing is the only system available for the removal of lint and dust directly before the printing process. Lint and dust removal is undertaken directly before the flat screen printing process whilst the fabric is at the printing table.

No other system can offer this unique facility in reducing printing faults and improving output.

Specifications

| Process Widths | 1200 – 3200mm |

| Process Speeds | 5 – 50 metres/min |

| Power Supplies | 380-415v 50Hz 460-480v 60Hz |

| Power Rating | 6KW |

| Water Consumption | 1.5 Litres/min |

| Water Connection | 15mm |

| Air Supply | 2 – 8 bar (6mm) |

| Discharge Connection | 50mm |

ROTOVAC FOR ROTARY PRINTING

FREE delivery on all orders over £75

Delivery in 2-3 working days

The second generation ROTOVAC offer maximum effectiveness for lint and debris removal from pre-printed fabric. They are available for both Rotary and Flat screen printing systems and suit all fabric types, process speeds and process widths.

New advanced technology within the ROTOVAC include a self cleaning vacuum system, designed to continually discharge the lint contaminated water ensuring continual operation with minimal operator intervention. Additionally the electronic control system is self monitoring so ensures maximum effectiveness during operation.

These together with a light weight durable construction and ease of installation make it the most advanced system for lint, dust and debris removal on the market today.

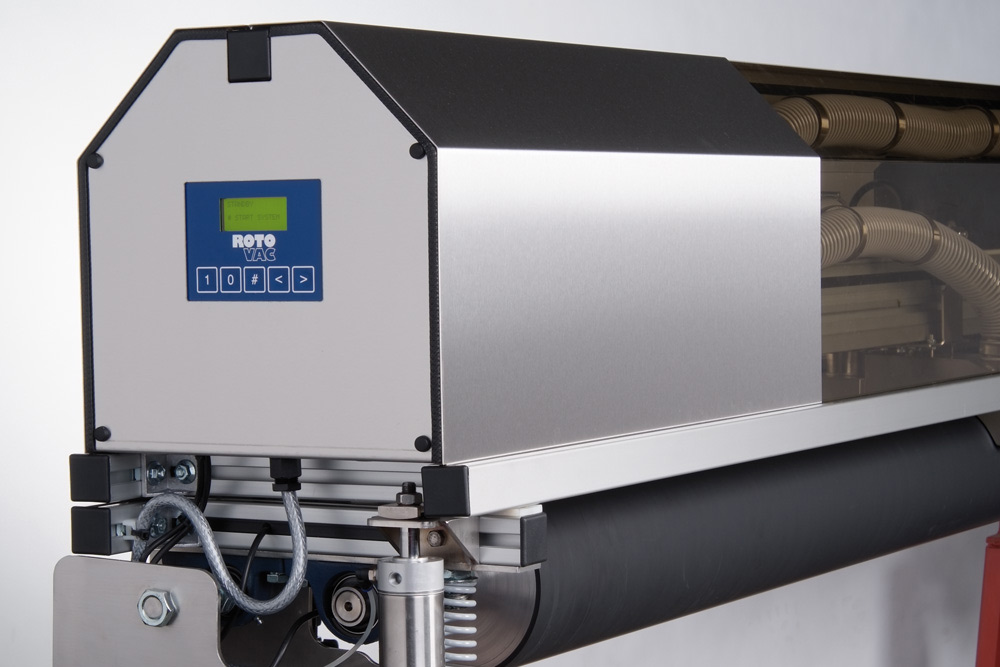

The ROTOVAC control pack can be positioned in any location around the ROTOVAC roller system. It is supplied as standard with 5 meters of service connections so only requires an electrical connection, clean water and compressed air to become fully functional.

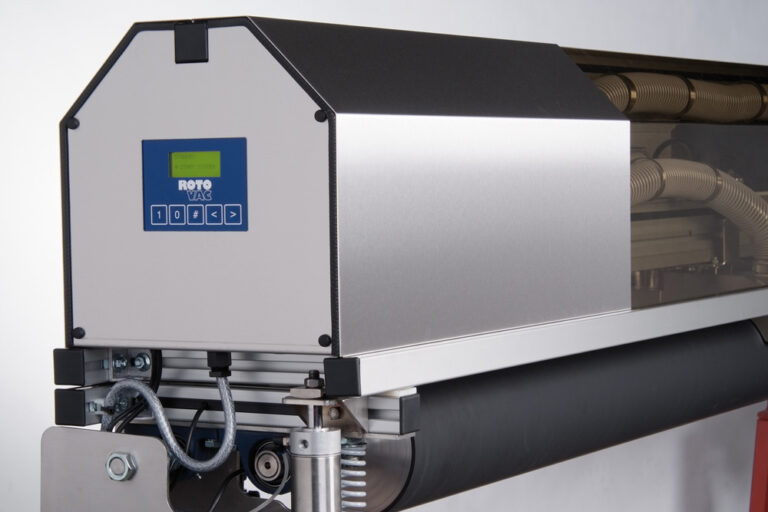

Clear screen display with continual information ensures optimal performance and ease of operation.

Features & Benefits

Advanced

An operator interface with advanced electronic control and clear view display panel, allows a total control of all ROTOVAC functions. The system is also equipped with self diagnostic software to ensure performance is maintained whilst offering continual running. Automatic start / stop systems work in connection with the print machine or process line requirements to minimise operator intervention.

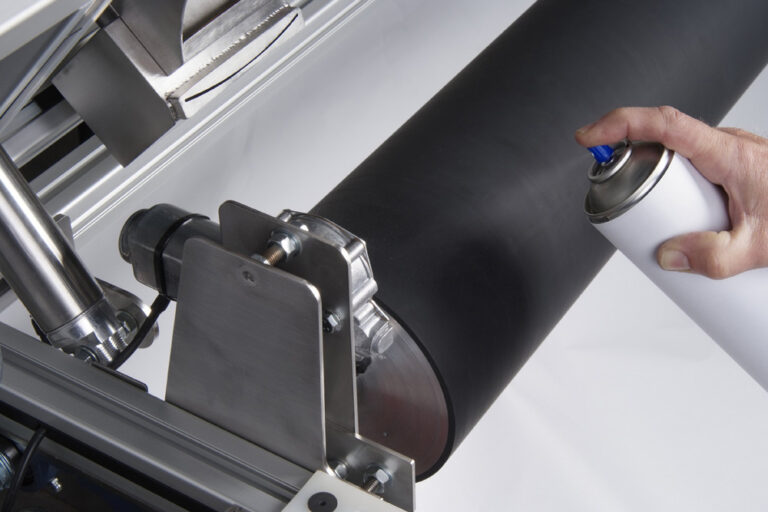

Additionally the multi-functional control panel offers a roller cleaning and adhesive application mode to ensure performance and speeds are optimised.

Precision

Electronic roller cleaning limit positions maximise the available performance for the lint and dust removal, ensuring the effected lint pick up area of the roller is continually cleaned. Linked also with periodic full roller cleaning ensures minimal build up of debris occur to the outer roller edges.

Left and Right handed operator stations are available at time of order, depending on print machine configuration and specific customer requirements.

Unique

The unique roller floatation design ensures maximum lint and dust removal, it ensures all fabric types can be processed without causing fabric distortion or damage.

Roller cleaning speeds and lint removal rates are easily variable, depending on fabric types and the process final requirements. Factory default settings are installed to ensure performance is guaranteed on installation and start up.

Control

Machine installation is made simple to minimise line stoppage times. Access to the roller unit is also made simple so cleaning can be effected on a regular bases with a minimal stoppage time.

All service connections are located for ease of installation and inspection.

Finally the adhesive application is assisted with the pneumatically lifted cover and automated roller rotation during application. This provides both a consistent and regular adhesive surface, with minimal stoppage or process down time.

Together this maximises lint, dust and debris removal and offers total control to the operator.

The above technical data relates to a standard ROTOVAC system.

For additional information relating to process widths or process speeds email our technical department at: ro*****@te*******.com

Specifications

| Process Widths | 1200 – 3200mm |

| Process Speeds | 5 – 100 metres/min |

| Power Supplies | 380-415v 50Hz 460-480v 60Hz |

| Power Rating | 6KW |

| Water Consumption | 1.5 Litres/min |

| Water Connection | 15mm |

| Air Supply | 2 – 8 bar (6mm) |

| Discharge Connection | 50mm |

ROTOVAC FOR TEXTILE PREPARATION

FREE delivery on all orders over £75

Delivery in 2-3 working days

Utilising the advanced technology of the ROTOVAC system it has become possible to offer a standalone system for the continual cleaning and preparation of textile fabrics prior to the coating and finishing processes.

The ROTOVAC standalone system offers maximum flexibility to clean lint and dust from fabric prior to any treatment process.

Features & Benefits

Flexible

Utilising the advanced technology of the ROTOVAC system it has become possible to offer a standalone system for the continual cleaning and preparation of textile fabrics prior to the coating and finishing processes.

The ROTOVAC standalone system offers maximum flexibility to clean lint and dust from fabric prior to any treatment process.

Independent

Designed and constructed as a standalone unit, ROTOVAC can now be installed to clean conventional and technical fabrics prior to the coating or laminating.

The removal of lint and dust is maximised through the ROTOVAC technology, a technology already widely used around the world for the continual cleaning of fabric prior to rotary screen printing.

This advanced technology is now made available as an independent system through continued product development.

Control

Added controls and construction ensures the textile process is not affected by alignment or tension issues. The fully adjustable design allows for precise and final adjustments at the time of installation to ensure the highest effect for the removal of lint and dust.

This new development offers all the standard facilities and controls found on a standard ROTOVAC system. Together leading to process and quality improvements of the end product and production facility.

Specifications

| Process Widths | 1200 – 3200mm |

| Process Speeds | 5 – 50 metres/min |

| Power Supplies | 380-415v 50Hz 460-480v 60Hz |

| Power Rating | 6KW |

| Water Consumption | 1.5 Litres/min |

| Water Connection | 15mm |

| Air Supply | 2 – 8 bar (6mm) |

| Discharge Connection | 50mm |