ROTARY SCREEN WASHERS

Purpose built from stainless steel and corrosive resistant material the Rotary Screen wash systems are designed to suit the individual needs of the industry for the effectively washing and cleaning Rotary screens.

Available for fully automatic or manual operation the machines are designed with the options to wash either water or solvent based paints, pigments or inks. The unique patented nozzle design offers the highest quality of cleaning available on to day’s market allowing blockages to be removed without damage or distortion of the screen.

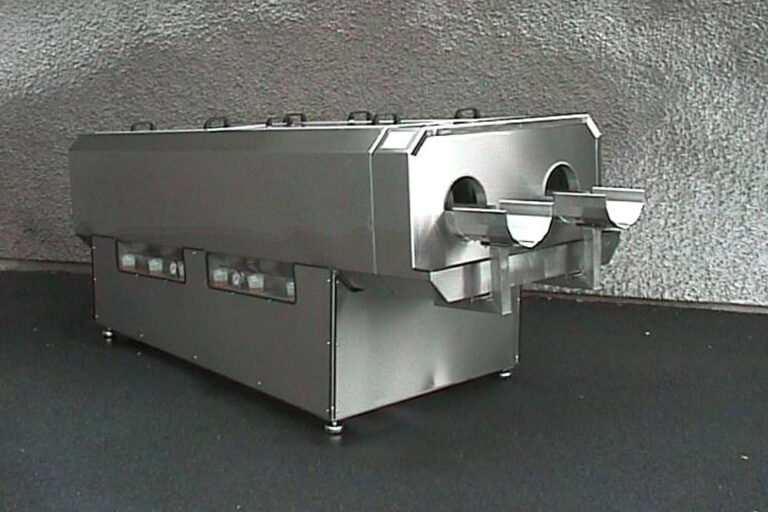

Double Rotary Screen Washer

- Double Screen Wash

- Excepts screen repeat sizes from 640mm to 1018mm

- Excepts print widths from 1620mm to 3200mm

- Unique patented spray nozzle releases a high quality cleaning action

- Minimises screen damage with no internal moving parts

- Low water consumption saving up to 25% compared with conventional washing

- Wash achieved in less than 1 minutes with no brushes or scrubbing action

- Minimum operator involvement

- Increases production capability

Manual Rotary Screen Washer

- Manual cost effective washing of screens

- Solvent or water based operation

- Excepts screen repeat sizes from 640mm to 1018mm

- Excepts print widths from 1620mm to 3200mm

- Unique patented spray nozzle releases a high quality cleaning action

- Minimises screen damage with no internal moving parts

- Low water consumption saving up to 25% compared with conventional washing

- Wash achieved in less than 1 minutes with no brushes or scrubbing action

- Minimum operator involvement

- Increases production capability

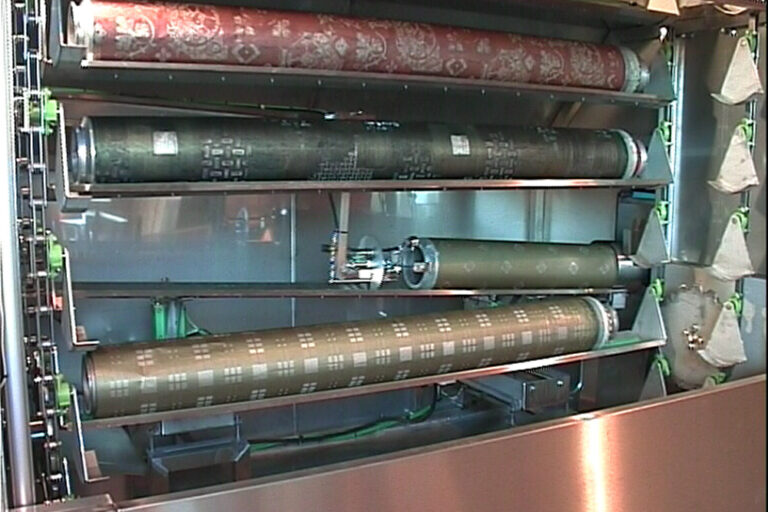

Automatic Rotary Screen Washer

- Full automated transportation-selection and washing of screens

- Cleans a maximum of 20 screens in one cycle

- Solvent or water based operation

- Excepts screen repeat sizes from 640mm to 1018mm

- Excepts print widths from 1620mm to 3200mm

- Minimises screen damage

- Low water consumption saving up to 25% compared with conventional washing

- Wash achieved in less than 2 minutes

- Minimum operator involvement with full PLC control

- Increases production capabilities